can rfid be used for automation tracking system RFID can be used in any application where you need to identify, locate and track products, assets or materials. It’s often used in warehouses, distribution centers, and retail to automate inventory and eliminate manual barcode scanning and cycle counts. Posted on Nov 1, 2021 12:10 PM. On your iPhone, open the Shortcuts app. Tap on the Automation tab at the bottom of your screen. Tap on Create Personal Automation. Scroll down and select NFC. Tap on Scan. Put .

0 · what is rfid technology

1 · rfid tracking software

2 · rfid technology in supply chain

3 · rfid technology in manufacturing

4 · rfid in shipping industry

5 · rfid for tracking

6 · benefits of rfid in logistics

7 · advantages of rfid technology

Therefore, your device is scanning for NFC tags, when the screen is on , so power would be used. My guess , is that this power consumption would be low, and not cause a drain .

You don’t need to line up a scanner to read an RFID tag. Tags are read wirelessly and remotely, even if they’re not physically visible or . See moreRFID can be used in any application where you need to identify, locate and track products, assets or materials. It’s often used in . See moreRFID requires a sizable investment, but the resulting gains in efficiency, tracking accuracy, and automation often generate a significant return on investment. To determine if RFID is . See more Transitioning to an RFID-based asset tracking system requires careful planning and execution. This section outlines a step-by-step approach for businesses looking to implement .

RFID can be used in any application where you need to identify, locate and track products, assets or materials. It’s often used in warehouses, distribution centers, and retail to automate inventory and eliminate manual barcode scanning and cycle counts.

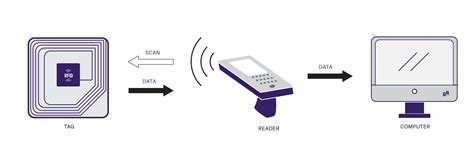

Transitioning to an RFID-based asset tracking system requires careful planning and execution. This section outlines a step-by-step approach for businesses looking to implement RFID for asset location and tracking effectively.Radio frequency identification (RFID) is a technology that uses radio waves to automatically identify and track assets. RFID helps to digitize supply chains as the technology generates automated sensor data that can be further analyzed for automation and optimization. RFID technology functions by identifying the presence of an object, recording the data, and storing that information ( . Integrating an RFID infrastructure with existing systems in manufacturing and supply chain companies can unlock a wide range of benefits, including real-time inventory visibility, improved asset management, enhanced process efficiency, and better quality control and traceability.

RFID (Radio Frequency Identification) tracking systems are designed to improve the efficiency and accuracy of tracking and managing assets in manufacturing environments. By using radio waves, these systems can identify and track objects automatically, providing real-time data and insights.RFID technology facilitates inventory management, process automation, and quality control in manufacturing. Manufacturers use RFID tags to track raw materials, work-in-progress items, and finished goods, enabling real-time monitoring of production processes, improving inventory accuracy, and reducing operational inefficiencies. RFID provides automated asset management by allowing for continuous and accurate monitoring. RFID can read multiple tags simultaneously. This capability simplifies asset tracking, reduces labor costs and minimizes the risk of asset loss or misplacement.With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

rf label tag

By providing unparalleled visibility and automation, RFID enhances operational efficiency, minimizes errors, and enables precise inventory management.RFID can be used in any application where you need to identify, locate and track products, assets or materials. It’s often used in warehouses, distribution centers, and retail to automate inventory and eliminate manual barcode scanning and cycle counts. Transitioning to an RFID-based asset tracking system requires careful planning and execution. This section outlines a step-by-step approach for businesses looking to implement RFID for asset location and tracking effectively.

Radio frequency identification (RFID) is a technology that uses radio waves to automatically identify and track assets. RFID helps to digitize supply chains as the technology generates automated sensor data that can be further analyzed for automation and optimization. RFID technology functions by identifying the presence of an object, recording the data, and storing that information ( . Integrating an RFID infrastructure with existing systems in manufacturing and supply chain companies can unlock a wide range of benefits, including real-time inventory visibility, improved asset management, enhanced process efficiency, and better quality control and traceability.

RFID (Radio Frequency Identification) tracking systems are designed to improve the efficiency and accuracy of tracking and managing assets in manufacturing environments. By using radio waves, these systems can identify and track objects automatically, providing real-time data and insights.

RFID technology facilitates inventory management, process automation, and quality control in manufacturing. Manufacturers use RFID tags to track raw materials, work-in-progress items, and finished goods, enabling real-time monitoring of production processes, improving inventory accuracy, and reducing operational inefficiencies. RFID provides automated asset management by allowing for continuous and accurate monitoring. RFID can read multiple tags simultaneously. This capability simplifies asset tracking, reduces labor costs and minimizes the risk of asset loss or misplacement.With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

what is rfid technology

rfid tracking software

rf tag with lanyard

Nov 11, 2024. In today’s rapidly evolving financial technology landscape, Samsung Pay and Google Pay have emerged as two of the most prominent players in digital transactions. These innovative platforms are at the .The NFC antenna on your smartphone may be located differently depending on the brand and model you have. Below, you'll find links to the manufacturers' websites where you can find more helpful info.

can rfid be used for automation tracking system|rfid technology in supply chain